How Long Does It Take to Build a Custom Speaker?

Share

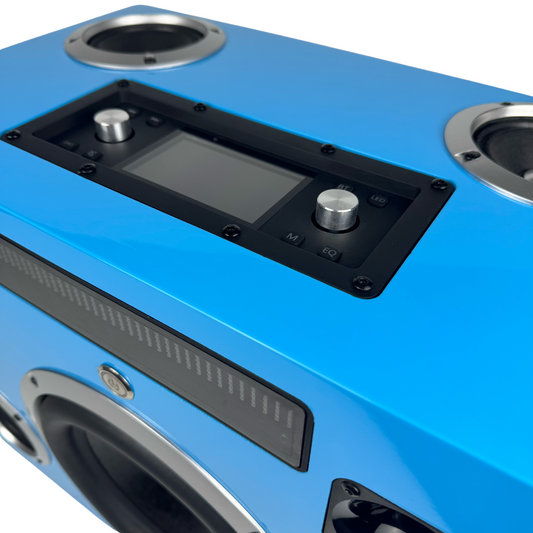

When embarking on a custom speaker project, one of the most common questions customers have is: How long does it take to build a custom speaker? The answer, however, is not straightforward, as the time required depends on several factors. From small and simple projects to large, complex business projects, the design, manufacturing process, and materials used all influence the timeline. In this blog, we'll break down the different stages of custom speaker development, explore how various factors impact the timeline, and explain how we ensure customer satisfaction throughout the entire process.

For a more detailed timeline, please visit this blog: The Timeline of Building a Custom Speaker: Step-by-Step Guide.

Custom Speaker Timelines: Small and Simple Projects

For smaller, more straightforward custom speaker projects—such as those designed for personal use or simple business needs—the timeline is relatively short compared to large-scale or highly complex speaker designs. Here’s a breakdown of what to expect in terms of time for the design and manufacturing processes.

1. Design Phase: 4 Weeks

The design phase typically takes around 4 weeks for small and simple projects. During this stage, we work closely with the client to gather their requirements, understand their audio needs, and conceptualize the speaker design. This includes determining the size, shape, audio specifications, and the materials to be used for the speaker. It’s during this phase that our team focuses on ensuring the design meets both the functional and aesthetic preferences of the customer.

To create a custom speaker that meets specific needs, we also conduct research into the latest audio trends, user preferences, and any unique requirements the customer may have. By the end of this 4-week period, we aim to have a finalized speaker design that can move on to the manufacturing phase.

2. Manufacturing Phase: 8-12 Weeks

Once the design is approved, the manufacturing phase typically takes between 8 to 12 weeks for small projects. During this phase, we create a prototype and begin producing the individual components of the speaker, including the enclosure, drivers, amplifier systems, and any additional features like LED displays or custom tweeter designs.

Throughout the manufacturing process, we continue to refine and polish the details of the speaker to ensure that it meets the client’s expectations. This may involve adjusting the materials, making fine-tuned changes to the audio components, and ensuring that every detail of the speaker is aligned with the original design. Since our custom speakers are tailored to each client, this step is critical to achieving the best possible performance.

During the manufacturing phase, we also stay in constant communication with the client, providing regular updates on the progress of their project. This ensures transparency and keeps the customer involved at every stage of the process.

3. Quality Assurance and Final Modifications

Before delivering the final product, we conduct rigorous quality assurance tests to ensure that the custom speaker meets all necessary standards. We test the sound quality, durability, and functionality to ensure that it meets the highest industry standards. Any final modifications are made at this point, ensuring that the client receives a flawless product.

Custom Speaker Timelines: Large and Complex Projects

For large custom speaker projects, particularly those intended for business use, the timeline can vary significantly based on the complexity of the design. In some cases, building a large custom speaker system can take months or even years. This is often the case for projects that require intricate audio setups, custom amplifier systems, and high-end materials.

1. Design Phase: Months to Years

The design phase for large projects can be lengthy, often taking several months or even years depending on the complexity of the design and the client's needs. For business clients, custom speakers are often built to accommodate large venues, professional audio systems, or specialized applications. In these cases, the design process involves a great deal of collaboration, research, and prototyping.

During this phase, we may work with architects, sound engineers, and business owners to ensure that the custom speaker system is perfectly suited to its intended environment. This could involve extensive testing, multiple rounds of design iterations, and the use of specialized materials or components.

2. Manufacturing Phase: Several Months

Manufacturing large, complex custom speakers takes much longer than small-scale projects. The process can take several months depending on the intricacies of the design, the materials used, and the production requirements. During this phase, we might need to manufacture large quantities of components, including custom drivers, enclosures, and specialized amplifiers.

For large-scale projects, the manufacturing phase is not just about building the speaker itself but also testing its performance in real-world environments. This ensures that the final product meets the client’s expectations and performs optimally in the intended space.

How Materials Impact the Time and Cost of Custom Speaker Projects

The materials used in the construction of a custom speaker can significantly impact both the time it takes to complete the project and the overall cost. Certain materials, such as plastic and wood, require different manufacturing processes, each with its own timeline.

1. Plastic: Molding Takes Time

If a client requests a plastic enclosure for their custom speaker, the production time can be longer than using other materials like wood. This is because creating a plastic enclosure involves the molding process, which requires designing and creating molds before mass production can begin. The molding process is more time-consuming and adds additional steps to the manufacturing phase.

Plastic is also more expensive than wood due to the cost of creating custom molds. However, plastic enclosures may offer benefits in terms of design flexibility and durability, making them a popular choice for certain types of custom speakers.

2. Wood: A Quicker, More Cost-Effective Material

For clients who opt for wooden enclosures, the manufacturing process is typically quicker because wood does not require a molding process. Instead, wood can be easily shaped, cut, and assembled to meet the desired design specifications. Wood is also generally more cost-effective than plastic, making it a popular choice for both small and large custom speaker projects.

Wooden enclosures provide excellent sound quality, especially for high-performance speakers, and their natural aesthetic can enhance the overall appearance of the speaker. However, the type of wood used and any additional custom finishes or coatings can still impact both the time and cost of the project.

Customer Satisfaction: Our Top Priority

At every stage of the custom speaker development process, customer satisfaction is our top priority. We understand that building a custom speaker is an investment, and we are committed to ensuring that every client is completely satisfied with the final product.

1. Tracking the Project From Start to Finish

From the moment a project begins, we take great care to track the progress of the design and manufacturing phases. Our team works closely with clients to gather their input, provide regular updates, and address any concerns that may arise. Whether the project is small and simple or large and complex, we stay in constant communication to ensure that the client is informed and involved throughout the process.

We also use project management tools to monitor timelines and ensure that every phase of the custom speaker build is progressing according to schedule. This allows us to stay on track and deliver the final product within the agreed-upon timeframe.

2. Polishing the Details

We understand that details matter, and that’s why we go the extra mile to ensure that every custom speaker we produce is polished to perfection. Whether it’s fine-tuning the audio performance, adjusting the aesthetic design, or ensuring that the materials meet the client’s expectations, we are committed to creating the best possible product.

Throughout the manufacturing process, we keep refining the speaker’s components to ensure that they meet the high standards we set for all our products. This attention to detail is what sets us apart and guarantees customer satisfaction.

3. Ensuring Transparency

One of the keys to our success is maintaining transparency with our clients. From the initial design consultation to the final product delivery, we make sure that our clients are aware of every step of the process. This includes providing detailed updates on the project’s status, estimated delivery times, and any potential challenges that may arise.

By maintaining open lines of communication, we ensure that the client feels confident in the progress of their custom speaker project.

Conclusion: How Long Does It Take to Build a Custom Speaker?

The time it takes to build a custom speaker varies based on the project’s complexity, the materials used, and the specific needs of the client. For small and simple projects, the process may take as little as 12 to 16 weeks from design to completion. Larger projects, especially those for business or professional use, can take several months or even years, depending on the level of customization required.

Materials also play a critical role in determining the timeline. For example, plastic enclosures take longer to produce due to the need for custom molding, while wooden enclosures offer a quicker and more cost-effective solution.

Regardless of the project’s scope, our focus is always on customer satisfaction. We work closely with our clients to track the entire process from start to finish, ensuring that the final product meets their expectations. If you’re considering a custom speaker project and would like to learn more about the timeline and process, don’t hesitate to contact us—we’re here to help you every step of the way.