Emerging Innovations in Speaker Manufacturing: Trends and Technologies

Share

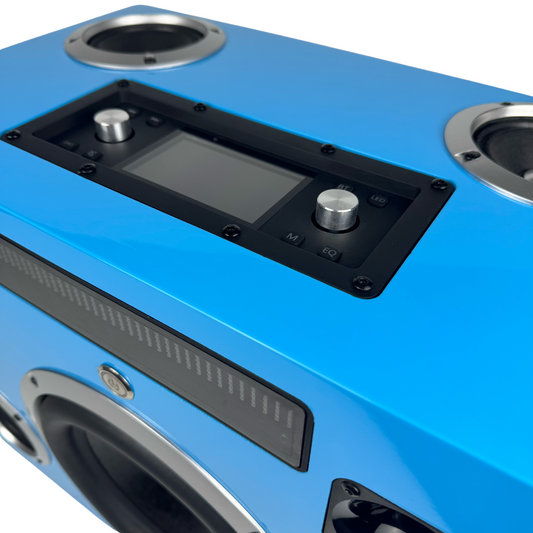

Emerging innovations in speaker manufacturing are rapidly transforming an industry that has long relied on traditional materials and methods. Today’s manufacturers are embracing cutting‑edge technologies—from advanced materials to smart production techniques—to create speakers that not only deliver superior sound but also integrate seamlessly into modern, connected lifestyles.

One of the most significant trends is the adoption of innovative materials in speaker design. Historically, diaphragm materials like paper and polypropylene dominated the market. However, research into graphene and carbon nanotubes is changing that landscape. Graphene, for instance, offers an extraordinary stiffness‑to‑weight ratio, which can reduce distortion and deliver a more precise audio reproduction. Early tests and industry insights suggest that speakers incorporating graphene diaphragms can achieve a broader, more dynamic sound profile, setting new benchmarks for high‑fidelity performance. These advancements in material science are helping manufacturers push the boundaries of what’s possible in sound quality.

At the same time, additive manufacturing—commonly known as 3D printing—is revolutionizing how speakers are prototyped and produced. With 3D printing, manufacturers can create intricate, optimized designs that traditional molding or machining techniques would find challenging or impossible. This technology not only accelerates the prototyping phase but also allows for more customized speaker enclosures and components tailored for optimal acoustic performance. By reducing lead times and enabling rapid design iterations, 3D printing is making it easier for companies to innovate and bring new products to market faster.

Another emerging trend is the integration of smart technology into speaker systems. As consumers increasingly demand seamless connectivity and voice‑control features, manufacturers are incorporating built‑in voice assistants and wireless connectivity options into their products. Modern speakers are now expected to work effortlessly with smart home ecosystems, supporting platforms like Amazon Alexa, Google Assistant, and Apple HomeKit. This convergence of audio performance and smart technology not only enhances user convenience but also creates a more interactive, immersive experience. The push toward smart speakers is fueling innovation across the production process, from design to assembly.

Sustainability has also become a key focus in speaker manufacturing. With environmental concerns on the rise, many companies are rethinking their production practices and materials. Innovations in using recycled plastics, biodegradable components, and energy‑efficient manufacturing processes are gradually being integrated into production lines. These eco‑friendly practices not only help reduce the environmental footprint but also resonate with a growing base of environmentally conscious consumers who expect quality products that are responsibly made.

Lastly, the rise of automation and artificial intelligence (AI) is streamlining production in speaker factories. Modern facilities increasingly employ robotic assembly lines and AI‑driven quality control systems to ensure precision, minimize waste, and reduce costs. These technologies not only improve consistency and output but also allow manufacturers to allocate resources toward further innovation and research.

In summary, the speaker manufacturing industry is undergoing a profound transformation driven by advanced materials, 3D printing, smart integration, sustainable practices, and AI‑powered automation. These emerging innovations are setting new standards in audio performance and production efficiency, paving the way for the next generation of high‑quality speakers that meet the demands of today’s discerning consumers.