What Are the Best Materials for Loudspeaker Cones?

Share

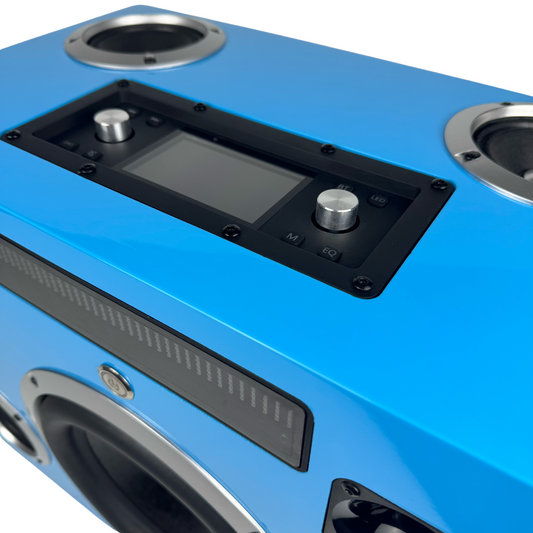

The loudspeaker cone, also known as the diaphragm, plays a crucial role in sound production, as it is responsible for converting electrical signals into sound waves. One of the most important aspects of loudspeaker design is the choice of material for the cone, as different materials can have a significant impact on the sound quality, performance, and durability of the speaker. In this blog, we’ll explore some of the most common materials used for loudspeaker cones, discussing their unique characteristics, advantages, and disadvantages. This information will help you make informed decisions when choosing or designing a loudspeaker for your audio needs.

1. Paper Cones

Overview:

Paper, also known as pulp, is one of the oldest and most commonly used materials for loudspeaker cones. Despite the development of modern alternatives, paper cones remain popular due to their well-balanced performance characteristics and natural sound.

Pros:

- Natural Sound Quality: Paper cones are known for delivering a warm and natural sound. They tend to produce smooth mid-range frequencies, which is why they are often favored in full-range speakers.

- Lightweight and Responsive: Paper cones are relatively light, making them highly responsive to audio signals. This results in efficient sound production and better control over the audio output.

- Customizability: Paper cones can be treated with different coatings, such as resins or polymers, to alter their performance. These treatments can improve the cone's stiffness and durability, enhancing sound quality and extending the speaker’s lifespan.

Cons:

- Susceptibility to Moisture and Humidity: One of the biggest drawbacks of paper cones is their vulnerability to environmental factors. Without proper treatment, paper can absorb moisture, leading to degradation in sound quality and potential warping.

- Less Durable Over Time: Compared to modern synthetic materials, untreated paper cones may degrade over time, especially in humid or damp environments.

Best Use Cases:

- Paper cones are ideal for indoor speakers where warmth and natural sound are prioritized, such as bookshelf speakers and mid-range drivers.

2. Polypropylene (Plastic) Cones

Overview:

Polypropylene is a type of plastic that has become a popular material for loudspeaker cones due to its durability, cost-effectiveness, and consistent performance. It is one of the most widely used synthetic materials in speaker manufacturing.

Pros:

- Durability and Resistance to Moisture: Polypropylene cones are highly resistant to environmental factors like moisture and humidity, making them a great choice for outdoor or marine speakers.

- Consistent Performance: Polypropylene cones provide reliable and consistent performance across a wide range of frequencies. They produce smooth sound, especially in the mid and low-frequency ranges.

- Affordable: Polypropylene is cost-effective to produce, making it a popular choice for entry-level and mid-range speakers.

Cons:

- Lack of Rigidity: One of the main drawbacks of polypropylene cones is that they are relatively soft compared to other materials. This lack of rigidity can lead to a slight loss of detail in the sound, especially in the high-frequency range.

- Less Responsive: Polypropylene is denser and heavier than paper, which can result in less responsiveness and lower overall efficiency.

Best Use Cases:

- Polypropylene cones are suitable for applications where durability is a priority, such as outdoor, marine, or car speakers. They are also commonly used in budget-friendly home audio systems.

3. Aluminum Cones

Overview:

Aluminum cones are often used in high-end loudspeakers because of their excellent rigidity and ability to handle high frequencies with precision. They offer a sleek, modern look and are widely used in both woofers and tweeters.

Pros:

- High Rigidity: Aluminum cones are very stiff, allowing them to move more precisely and produce highly accurate sound, particularly in the upper-frequency range. This results in crisp, detailed audio with minimal distortion.

- Excellent Heat Dissipation: Aluminum is highly efficient at dissipating heat, which is beneficial for maintaining consistent performance in high-power speakers.

- Durability: Aluminum cones are extremely durable and resistant to environmental factors like moisture and temperature changes.

Cons:

- Cold Sound Character: One of the common criticisms of aluminum cones is that they can produce a “cold” or “metallic” sound, lacking the warmth that paper cones typically provide.

- Heavier: Aluminum cones are heavier than paper or polypropylene cones, which can reduce efficiency in some speaker designs. This added weight requires more power to drive the speaker effectively.

- Cost: Aluminum cones tend to be more expensive to manufacture, which can increase the cost of the speaker.

Best Use Cases:

- Aluminum cones are ideal for high-end audio systems, studio monitors, and tweeters where precision and accuracy are more important than warmth.

4. Kevlar Cones

Overview:

Kevlar is a synthetic fiber known for its strength and durability, making it an excellent material for loudspeaker cones. Originally developed for use in body armor, Kevlar’s rigidity and lightweight properties make it a popular choice for high-performance speakers.

Pros:

- Extreme Strength and Durability: Kevlar is incredibly strong and resistant to wear and tear, making it one of the most durable materials used for speaker cones.

- Low Distortion: The high stiffness-to-weight ratio of Kevlar cones helps reduce distortion, resulting in clear, accurate sound across a wide frequency range.

- Lightweight: Despite its strength, Kevlar is lightweight, allowing for quick and efficient movement of the cone, which enhances responsiveness and overall sound quality.

Cons:

- Cost: Kevlar is a premium material, and speakers with Kevlar cones tend to be more expensive than those using other materials.

- Complex Manufacturing Process: Kevlar cones require a more complex manufacturing process, which can add to the overall production cost and lead time.

- Sound Profile: While Kevlar cones offer high clarity and precision, some listeners find them to be overly analytical, lacking the warmth and character of other materials.

Best Use Cases:

- Kevlar cones are best suited for high-performance home audio systems and professional audio applications where clarity and durability are essential.

5. Carbon Fiber Cones

Overview:

Carbon fiber is another advanced material known for its strength, rigidity, and lightweight properties. Carbon fiber cones are used in high-end loudspeakers to deliver exceptional sound performance.

Pros:

- High Strength-to-Weight Ratio: Carbon fiber is both strong and lightweight, making it ideal for producing fast, responsive sound with minimal distortion.

- Detailed Sound Reproduction: The rigidity of carbon fiber cones allows for highly detailed sound reproduction, especially in the mid to high-frequency range.

- Durability: Carbon fiber cones are resistant to environmental factors like temperature changes, humidity, and physical wear.

Cons:

- Expensive: Carbon fiber is one of the most expensive materials used for speaker cones, which can drive up the price of the speaker.

- Rigid Sound Profile: Similar to aluminum, carbon fiber cones can sometimes produce a “cold” or overly analytical sound that lacks warmth and character.

- Manufacturing Complexity: Like Kevlar, carbon fiber requires a complex and expensive manufacturing process, which can limit its use in mass-market speakers.

Best Use Cases:

- Carbon fiber cones are typically used in high-end speakers where performance, precision, and durability are prioritized over cost.

6. Composite Cones (Paper/Plastic Blends)

Overview:

Composite cones combine different materials, such as paper, polypropylene, or carbon fiber, to create a hybrid cone that takes advantage of the best properties of each material. These cones aim to balance sound quality, durability, and cost.

Pros:

- Balanced Performance: Composite cones are designed to offer a balance of strength, responsiveness, and sound quality, making them versatile and well-suited to a wide range of applications.

- Customizable Properties: By combining materials, manufacturers can fine-tune the performance characteristics of the cone to achieve the desired sound quality.

- Cost-Effective: Composite cones are often more affordable than pure materials like Kevlar or carbon fiber, offering high performance at a lower price point.

Cons:

- Compromises: While composite cones aim to balance performance, they may not excel in any one area as much as cones made from pure materials. For example, they may not be as warm as paper or as rigid as carbon fiber.

- Durability Variability: The durability of composite cones can vary depending on the materials used and the quality of construction.

Best Use Cases:

- Composite cones are ideal for mid-range speakers that require a balance of durability, performance, and affordability. They are commonly found in home audio systems and car speakers.

Conclusion: Choosing the Right Material for Your Custom Speaker

Selecting the right material for your loudspeaker cone is a critical decision that can significantly impact the sound quality, durability, and performance of your speaker. Each material comes with its own set of advantages and disadvantages, making it important to consider your specific audio needs and environment when making your choice.

- For natural, warm sound: Paper cones are a great option, especially for indoor environments.

- For durability and moisture resistance: Polypropylene and composite cones offer a balance of performance and durability, ideal for outdoor and budget-conscious applications.

- For high-end precision and clarity: Materials like aluminum, Kevlar, and carbon fiber deliver the best performance, though they come with a higher price tag and a more analytical sound profile.

Ultimately, the best material for your custom speaker depends on your personal preferences, budget, and intended use. If you’re unsure where to start, our team at DioDIY is here to help. We offer a range of customizable speaker components and can guide you through the process of selecting the ideal materials for your project. Contact us today for expert advice and to begin crafting your perfect sound system.