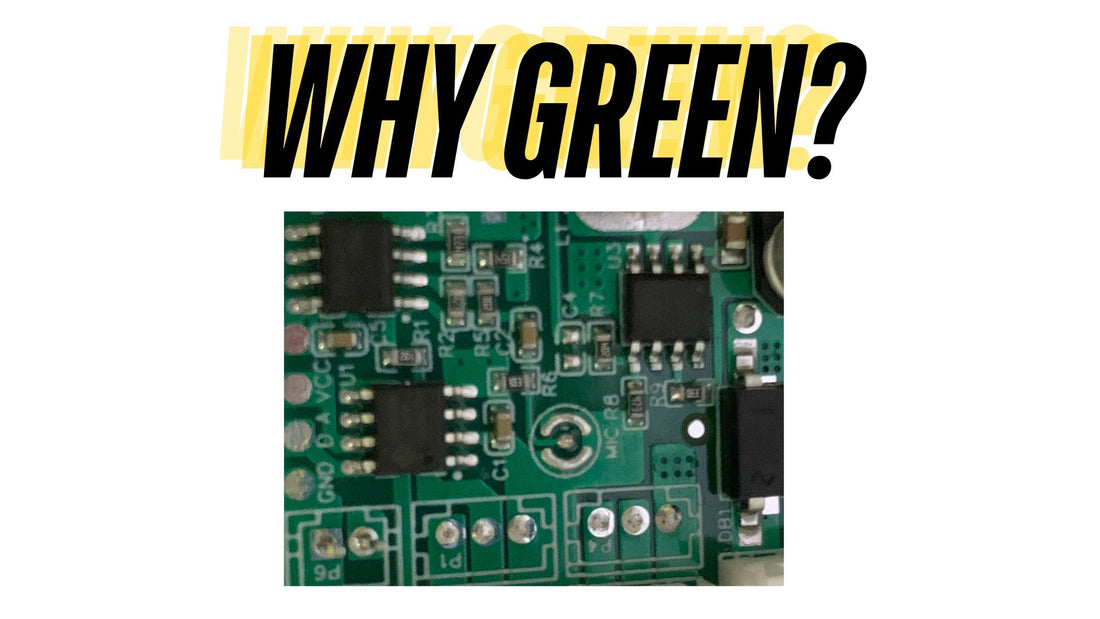

Why Are PCBs Green?

Share

When building a speaker setup or engaging in speaker manufacturing, you may have noticed that the internal circuit boards are often green. This isn’t unique to speakers; in fact, many electronics use green for their printed circuit boards (PCBs). Have you ever wondered why? In this blog, we’ll explore the historical reasons why green became the standard color for PCBs, whether it must always be green, and the implications of different PCB colors for speaker projects.

The Origin of Green in PCBs

The iconic green color of printed circuit boards (PCBs) is due to the solder mask, a protective layer applied to the board. The solder mask serves several purposes: it prevents accidental electrical shorts, shields the copper circuits from environmental damage, and ensures the board can be easily soldered without bridging connections. The reason green became the standard color can be traced back to a mix of historical, practical, and technical factors.

1. Historical Reasons

The use of green for PCBs dates back several decades, to the early days of electronics manufacturing. During the 1960s and 1970s, military and industrial electronics were the pioneers of PCB technology. The materials and processes available at that time led to the adoption of a green solder mask made from epoxy resin. Epoxy was favored for its durability, cost-effectiveness, and ability to provide reliable protection. The original formulation of epoxy resulted in a green hue, and over time, this became the de facto standard.

Another historical factor that influenced the color choice is that green was found to provide an optimal contrast for human visual inspection. Engineers and technicians needed to inspect solder joints, connections, and traces carefully. Green provided just the right balance—it wasn’t too dark, which could make details hard to see, and it wasn’t too bright, which could cause eye strain. This optimal contrast made the inspection process easier and more effective, which was crucial in an era where manual inspection was the primary quality control method.

2. Production Advantages

Another reason why PCBs are green lies in the manufacturing process. The chemicals used to make solder masks were optimized for green epoxy resins, and as production became standardized, manufacturers refined their processes around this green formula. Over time, this created economies of scale, making green solder mask the most affordable and widely available option.

Green PCBs have also demonstrated excellent chemical resistance, thermal stability, and UV protection, which are critical factors when it comes to making a reliable, long-lasting product. These qualities have helped establish green as the default color for most commercial electronics, including those used in speaker manufacturing.

3. Industry Standardization

As PCB production scaled up and became more widespread, the green solder mask was institutionalized across industries. Standards organizations, such as the IPC (Institute for Printed Circuits), established best practices for manufacturing and assembly. Green, being the most widely produced and tested color, met industry reliability standards, which further cemented its place in the world of electronics.

Because of these historical precedents, most PCB manufacturing facilities were optimized for green solder masks. Green became a symbol of quality and standardization, which meant that customers felt more comfortable with green PCBs compared to other colors. Even today, many manufacturers use green simply because it is what consumers expect, and deviation from this can be seen as an unnecessary risk.

It Doesn't Have to Be Green: Other PCB Colors

Although green is by far the most common color for PCBs, it’s important to note that PCBs can be produced in a variety of colors. These colors result from using different solder masks, which provide the protective coating over the copper traces. Common alternatives include red, blue, black, white, and even yellow. Each color can impact the manufacturing process, inspection efficiency, and potentially even thermal performance.

1. Red and Blue PCBs

Red and blue PCBs are often seen in consumer electronics that want to stand out visually. These colors provide good contrast for visual inspection, but not as well as green. They are often used to signify specialty or limited-edition products.

For example, if a custom speaker setup has a unique design, using red or blue PCBs may make it more visually appealing, especially if the internal electronics are meant to be showcased. Blue is also commonly chosen because it evokes a sense of quality and exclusivity, which is why high-end audio equipment sometimes features blue PCBs.

2. Black PCBs

Black PCBs are used in a lot of high-end products, including premium speaker manufacturing projects. Black is often associated with luxury and sophistication, which makes it an attractive choice for companies that want to market their products as premium or advanced. However, black solder masks can be more challenging to work with during the inspection process.

The black color of the PCB makes it harder to see traces and connections, which increases the likelihood of errors during both the manufacturing and the inspection processes. Additionally, black PCBs are known to absorb heat more readily, which can lead to higher operating temperatures if proper thermal management isn’t accounted for. This is an important consideration for speaker systems that generate a lot of power.

3. White and Yellow PCBs

White PCBs are sometimes used in products where aesthetics are crucial. They look great in transparent enclosures or products where the internal design is visible. However, the downside is that white PCBs tend to show dirt, smudges, and other imperfections more clearly, making them less practical for manufacturing environments.

Yellow PCBs are relatively rare but can be used to indicate a specific function or differentiate between components in complex assemblies. For instance, in a modular speaker design, a manufacturer might use different PCB colors to visually differentiate between the crossover circuit, the amplifier, and other modules.

Are Other PCB Colors Better for Speaker Manufacturing?

Choosing a different PCB color, such as red or black, doesn’t inherently make the speaker setup better or worse. The choice of color is primarily a matter of preference, manufacturing processes, and brand aesthetics. However, there are practical considerations that can affect speaker manufacturing:

- Heat Dissipation: As mentioned, black PCBs absorb more heat compared to lighter-colored PCBs. This can be an issue in high-power speaker systems where heat management is crucial. Green and blue PCBs tend to perform better in these situations due to their lower heat absorption.

- Inspection and Quality Control: Green offers the best visibility for inspecting solder joints and identifying defects, which is an important consideration for maintaining high-quality standards during the manufacturing of custom speaker components.

- Brand Image: For speaker manufacturers looking to create a distinct identity, using non-standard PCB colors can help set their products apart. For example, a brand that emphasizes cutting-edge design might opt for black or red PCBs to convey a sense of exclusivity and innovation.

DioDIY's Use of Green and Custom PCB Colors

At DioDIY, we focus on providing high-quality custom speaker components that meet both aesthetic and functional needs. While green PCBs are the industry standard for most of our components, we also offer other options for those interested in building a more personalized speaker setup.

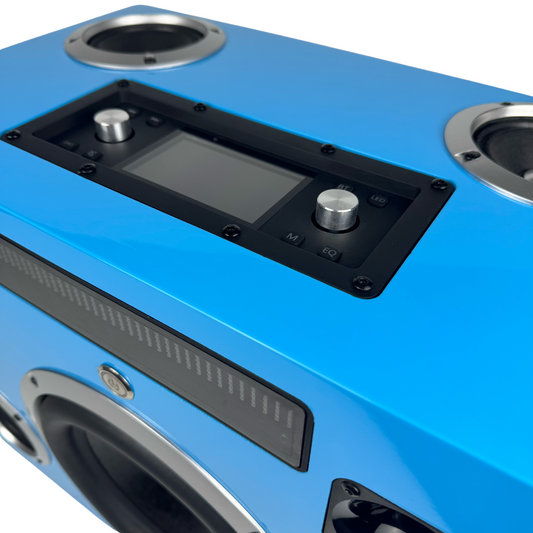

For instance, DioDIY’s 2.1 Amplifier Board with LCD Screen uses a green PCB, which provides excellent thermal stability and makes assembly and inspection easier. The choice of a green PCB for this product was intentional to ensure reliability and ease of use for DIY enthusiasts who want to focus on building an effective speaker system without dealing with unnecessary complexities.

However, for clients interested in customization, DioDIY can also offer PCBs in different colors to match the aesthetic needs of specific projects. Whether you’re looking for a red PCB to make your speaker setup stand out or a blue PCB to complement the rest of your components, DioDIY can accommodate your preferences.

Why Green Remains the Most Popular Choice

Despite the availability of other colors, green PCBs continue to dominate the market. This is due to several reasons:

- Cost Efficiency: Since green solder masks are the most commonly produced, they benefit from economies of scale. This makes them the most affordable option for both manufacturers and consumers.

- Performance Reliability: Green PCBs have a long history of reliability, with proven thermal and chemical stability. They perform well across a wide range of applications, including speaker setups, where consistent performance is crucial.

- Inspection Ease: The visual advantages of green PCBs make them an ideal choice for ensuring high-quality production. Given the importance of precise soldering and assembly in speaker manufacturing, the ability to easily inspect green PCBs helps reduce production errors and improve product quality.

- Established Standards: Many manufacturing standards were developed with green PCBs in mind. As a result, manufacturers stick with green because it’s been tested, certified, and validated over decades of use in various electronic applications.

Conclusion: Choosing the Right PCB for Your Speaker Setup

In the world of speaker manufacturing, PCB color may seem like a minor detail, but it has its own implications for cost, performance, and aesthetics. The green PCB is the industry standard for a reason—it’s cost-effective, reliable, and easy to work with, making it a practical choice for most applications.

However, choosing a different color can add an aesthetic edge or align with the branding of a product. For custom speaker projects where looks are as important as performance, exploring alternative colors like black, red, or blue can help your product stand out. At DioDIY, we strive to provide components that are both functional and visually appealing, offering various customization options to suit your project needs.

Whether you opt for a classic green PCB or a custom color to add flair to your speaker setup, understanding the history and reasoning behind these choices will help you make an informed decision. After all, a great speaker isn’t just about the sound—it’s also about the story behind how it was built.